ELECTRO CHLORINATION

ELECTRO CHLORINATION

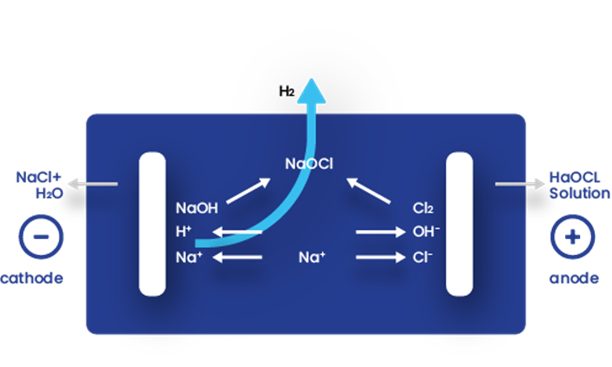

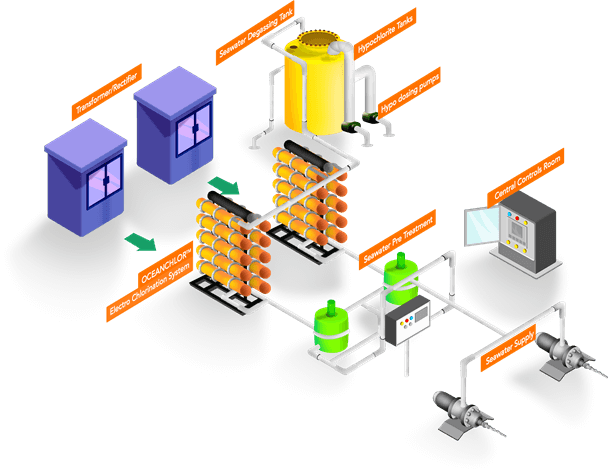

Sodium Hypochlorite is made up of sodium chloride and is a chlorine-containing compound that can be used as a disinfectant. It is produced when chlorine gas is dissolved in a sodium hydroxide solution. Our process is based on the electrolysis of seawater or brine as it flows through an unseparated electrolytic cell. The resulting solution exiting the cell is a mixture of seawater, sodium hypochlorite, hydrogen gas, and hypochlorous acid. Our process involves the generation of onsite sodium hypochlorite on the spot by the electrolysis of brine solution or natural seawater. Electro chlorination is used as an alternative method to gas chlorination to limit the usage of chlorine handling and maintenance.

Capco Water Solutions offers a best-in-class product suite depending on your application from ELECHLOR® Brine water electro-chlorination systems, OCENACHLOR® Sea water electro-chlorination systems, and ELECTROPAC® Onsite hypochlorite packages for offshore applications. Complete skid-based systems for ease of delivery and installations at the site.

ADVANTAGES

- Proven technology of electrolysis

- Inherently Dimensionally Stable

- Re-coating & Refurbishment

- Tailor Made Construction

- Corrosion Proof Engineering

- MMO Coated

- Industry leading electrolyzer design

- Operational efficiency

APPLICATION OF USE

- Industrial & Municipal

- Oil & Gas

- Offshore Platforms

- Water treatment facilities

- Textile/Steel/Pulp and Paper Industries

- Desalination facilities

- Power Plants

- Refineries

- Smart Cities/Colonies/Residential Towers

- Commercial swimming pool

- Pharmaceutical industries

- Liquefied Natural Gas Terminal (LNG)